When Lean Manufacturing Drives Success and Eliminates Waste

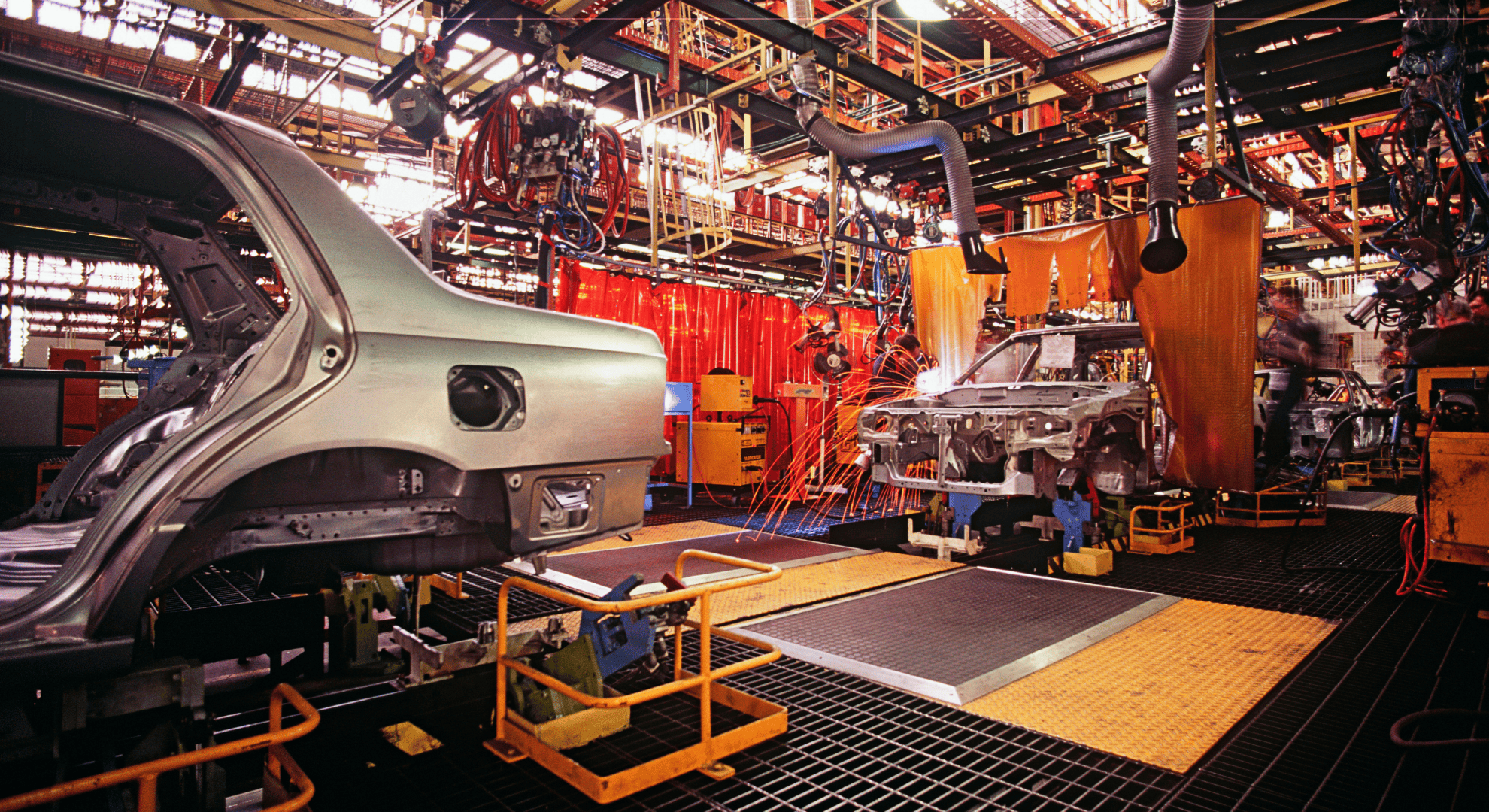

Manufacturing today is more competitive than ever. Companies that fail to streamline operations, eliminate waste, and enhance efficiency risk falling behind. This is where Lean Manufacturing comes in, a proven methodology that helps businesses reduce costs, improve quality, and boost overall productivity.

Lean Manufacturing, rooted in the Toyota Production System (TPS), focuses on eliminating inefficiencies while maximizing value for customers. Organizations worldwide have adopted its principles to improve workflow, minimize defects, and foster a culture of continuous improvement. But what makes Lean so powerful, and how can businesses apply its core principles for long-term success?

The concept of Lean is often misunderstood as merely cutting costs or increasing speed, but it is much more than that. Lean is about delivering value with fewer resources while maintaining or improving quality. It requires a shift in mindset, one that continuously seeks to identify inefficiencies, eliminate waste, and empower employees to make proactive improvements.

Despite its proven success, many companies struggle with implementing Lean effectively. Common challenges include resistance to change, lack of leadership commitment, and failure to integrate Lean into company culture. Without a structured approach, Lean can become just another short-term initiative rather than a long-term strategy for operational excellence.

However, businesses that truly embrace Lean see transformational results. From reducing production costs and improving delivery times to increasing employee engagement and customer satisfaction, Lean can create lasting benefits across the entire organization. Below, we explore the core principles of Lean Manufacturing and how they drive sustainable success.

The Core Principles of Lean Manufacturing

1. Eliminating the 7 Wastes

At the heart of Lean is the identification and elimination of waste (Muda)—any process or resource that does not add value. The seven types of waste include:

✅ Overproduction (making more than needed)

✅ Waiting (delays in the production process)

✅ Unnecessary transportation (moving materials inefficiently)

✅ Overprocessing (adding steps that do not add value)

✅ Excess inventory (holding more stock than necessary)

✅ Unnecessary motion (workers moving inefficiently)

✅ Defects (errors that require rework or scrap)

By addressing these waste areas, companies can streamline operations, lower costs, and improve customer satisfaction.

2. Continuous Flow and Just-in-Time (JIT) Production

Traditional manufacturing often relies on large batch production, leading to inefficiencies. Lean promotes Just-in-Time (JIT) manufacturing, ensuring that materials and products move through the system only when needed. This prevents overproduction, reduces inventory costs, and enhances responsiveness to customer demands.

Key JIT principles include:

✅ Takt Time: Aligning production speed with customer demand

✅ Pull System: Producing based on real-time demand rather than forecasts

✅ Leveled Production: Avoiding bottlenecks and ensuring a steady workflow

3. Building Quality Into the Process (Jidoka)

Lean emphasizes Jidoka, or “automation with a human touch,” which ensures quality is built into every step of the manufacturing process rather than relying on final inspections. By identifying problems early and stopping production when defects occur, manufacturers can reduce waste, prevent costly recalls, and improve reliability.

Key Jidoka strategies include:

✅ Standardized work processes to maintain consistency

✅ Error-proofing (Poka-Yoke) to minimize human errors

✅ Real-time problem-solving to address issues immediately

4. Empowering Employees Through Kaizen

Lean Manufacturing is not just about processes; it is about people. Companies that succeed with Lean foster a culture of Kaizen (continuous improvement), where employees at all levels actively contribute ideas for process enhancements.

Kaizen encourages:

✅ Daily improvements in small, incremental steps

✅ Problem-solving collaboration across teams

✅ Leadership involvement to drive long-term change

5. Data-Driven Decision-Making

Lean organizations rely on real-time data and performance indicators to measure efficiency and identify areas for improvement. Effective use of data ensures that decisions are made based on facts rather than assumptions, leading to greater operational control and better resource allocation.

Bottom Line

Lean Manufacturing is more than just a set of tools, it is a mindset and a cultural shift that drives efficiency, improves quality, and enhances customer satisfaction. Businesses that embrace Lean gain a competitive advantage by reducing costs, increasing flexibility, and delivering superior products.

If Lean Manufacturing is a key focus for your business, don’t miss Zenith Bizness Excellence’s upcoming Mastering Lean Practices for Manufacturing Industry Masterclass on 27 & 28 May 2025 at Royale Chulan Hotel, Penang. Led by Ben Sparrow, a Toyota Production System expert and Director of Shinka Management Pty Ltd., Australia, this masterclass provides invaluable insights from his 20+ years of experience in implementing Lean across industries worldwide. This highly practical program will equip you with real-world Lean strategies, case studies, and hands-on techniques to drive continuous improvement in your operations.

For more details, reach out to us at admin@zenithbizness.com or call +603 7890 5454.